The original pressure holding process of an electronic manufacturing company adopted the traditional operation mode: manually transporting semi-finished products to the static rack → manually recording the pressure holding time/using a timer → manually removing the carrier and transporting it again. This mode has problems such as high labor cost (4 people in shifts), low efficiency (single piece takes 3 minutes), misplacement and mistake, and safety hazards (3-5 falling accidents per year).

Automation transformation plan

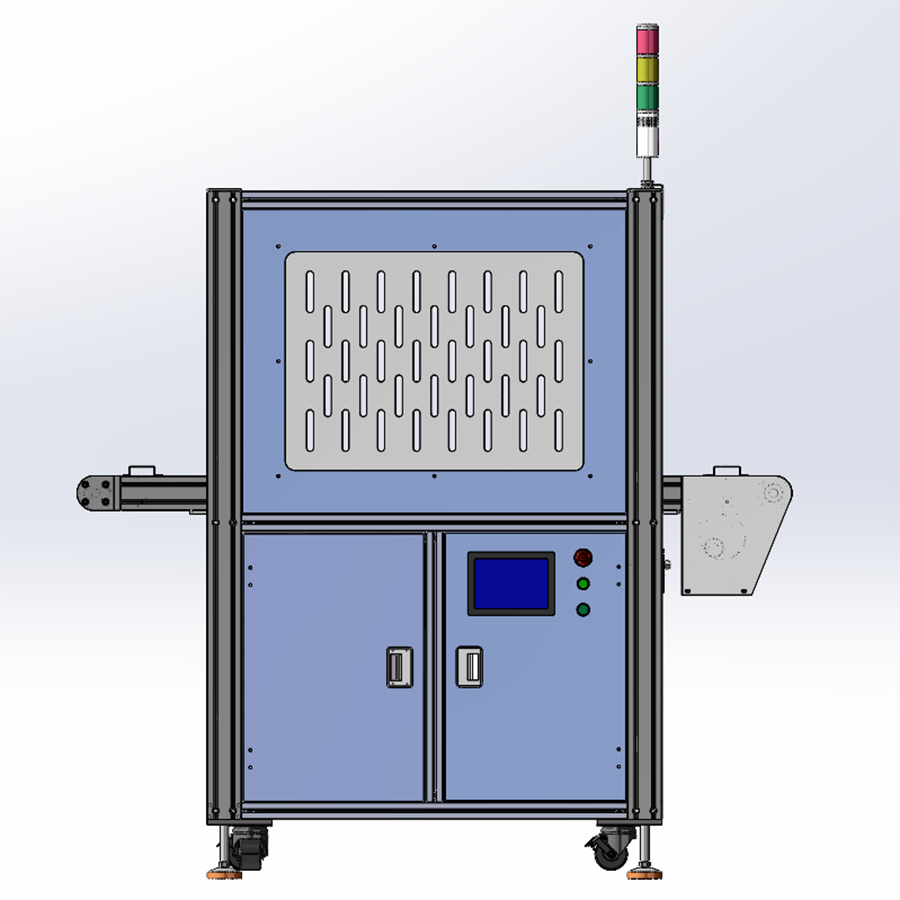

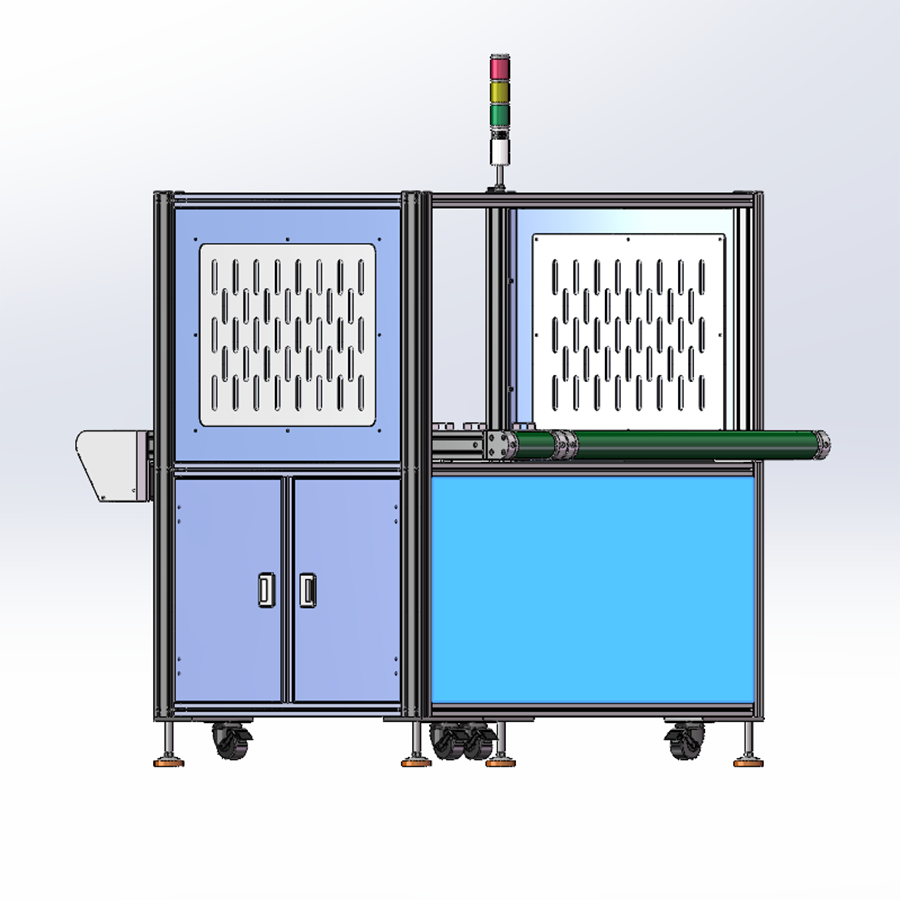

Equipment integration

Introduce the automatic pressure holding bed to connect with the line equipment to achieve seamless connection of the line, and at the same time parameterize the pressure holding time, add the PLC controller, and link with other equipment.

Key innovations:

Carrier circulation system: automatic return of the carrier is achieved through the conveying return line (the cycle time is shortened to 45 seconds)

Pressure holding time anti-fool mechanism: through parameter setting, no human intervention is required, the equipment runs automatically, and stops automatically when the time is up

Indicator Before and after transformation, the improvement rate of human resources configuration is reduced by 50%. Production capacity increased by 30%, error rate reduced by 0%, 0 work-related accidents/year

Experience summary

This solution achieves the dual goals of "reducing staff and increasing efficiency + improving quality" through equipment automation + carrier circulation system, with an investment payback period of about 6 months. It can be expanded to other process links that require timed pressurization in the future.