News

-

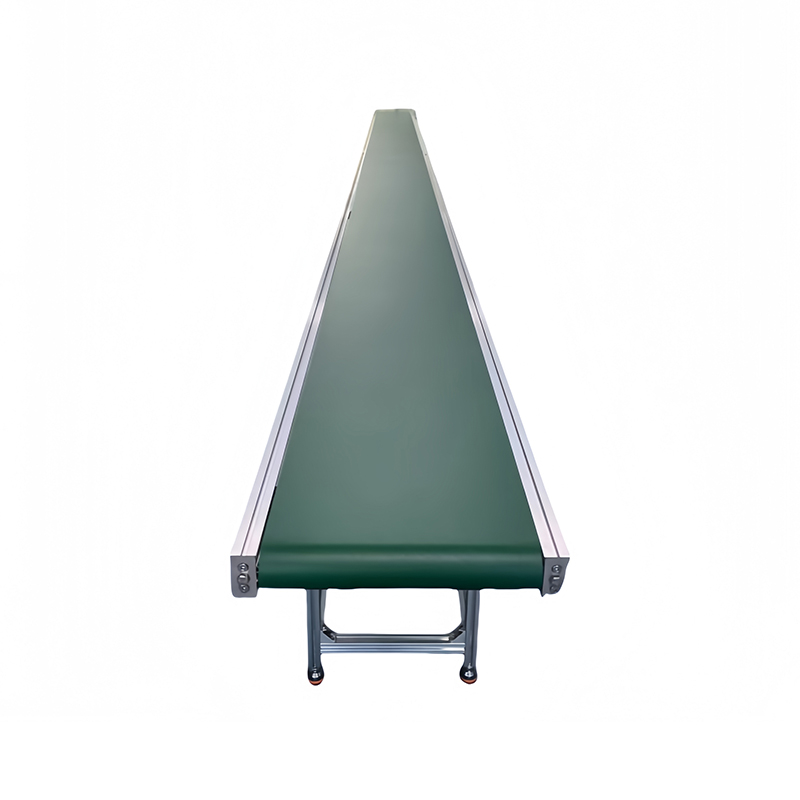

How can a 3C conveyor line balance the differences in production cycle time between different workstations through dynamic buffer design?

The application of dynamic buffer design in the 3C conveyor line not only solves the efficiency loss caused by the difference in workstation cycle time, but also improves the flexibility and adaptability of the production line.

Learn More2026-02-11 -

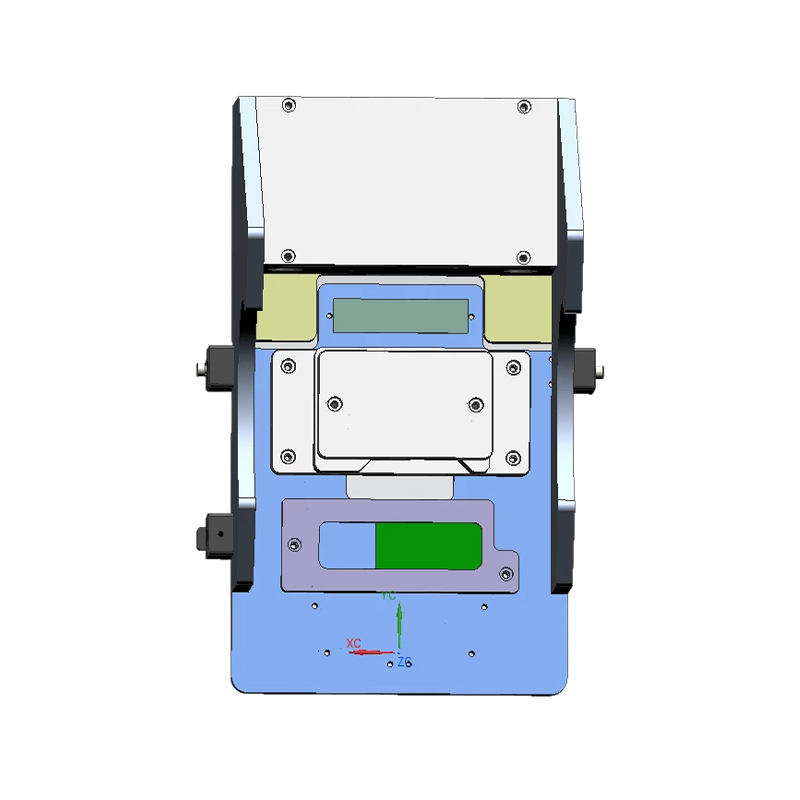

How can pressure bed equipment simultaneously maintain high precision and repeatability in parallel, vertical, and rotary movements during high-speed operation?

In 3C (computer, communication, and consumer electronics) product manufacturing, pressure bed equipment, as a key precision assembly unit, is widely used in processes such as screen bonding, camera module press-fitting, and battery packaging.

Learn More2026-01-30 -

How to design an anti-static device for a 3C conveyor line to prevent electronic components from being affected by static electricity?

The design of anti-static devices for 3C conveyor lines requires the construction of a six-in-one protection system encompassing materials, structure, grounding, environment, monitoring, and personnel.

Learn More2026-01-15 -

What crucial role do mobile phone fixtures play in ensuring the accuracy of bearing positioning in mobile phones?

Mobile phone fixtures—various structural and functional tooling fixtures—become the core support for ensuring assembly accuracy and improving yield rates. They not only firmly "lock" the phone body but also provide a stable and reliable physical platform

Learn More2025-12-31 -

How does a 3C conveyor line achieve unmanned, high-efficiency workflow and significantly increase production capacity?

In today's rapidly evolving landscape of 3C products such as smartphones, laptops, and wearable devices, manufacturers face not only the pressure of technological upgrades but also the extreme pursuit of production efficiency, consistency, and delivery sp

Learn More2025-12-18 -

How can pressure bed equipment integrating vertical, parallel, and rotational motion simplify the layout of 3C automated production lines?

Pressure bed equipment integrating vertical, parallel, and rotational three-degree-of-freedom motion is becoming a key tool for optimizing 3C production line layout and improving overall efficiency due to its high integration and multi-functionality.

Learn More2025-12-04