A leading mobile phone OEM factory faces three major pain points in traditional belt lines:

1. Static electricity causes breakdown of precision components

2. Manual transfer is required between production lines

3. Poor communication with automated equipment

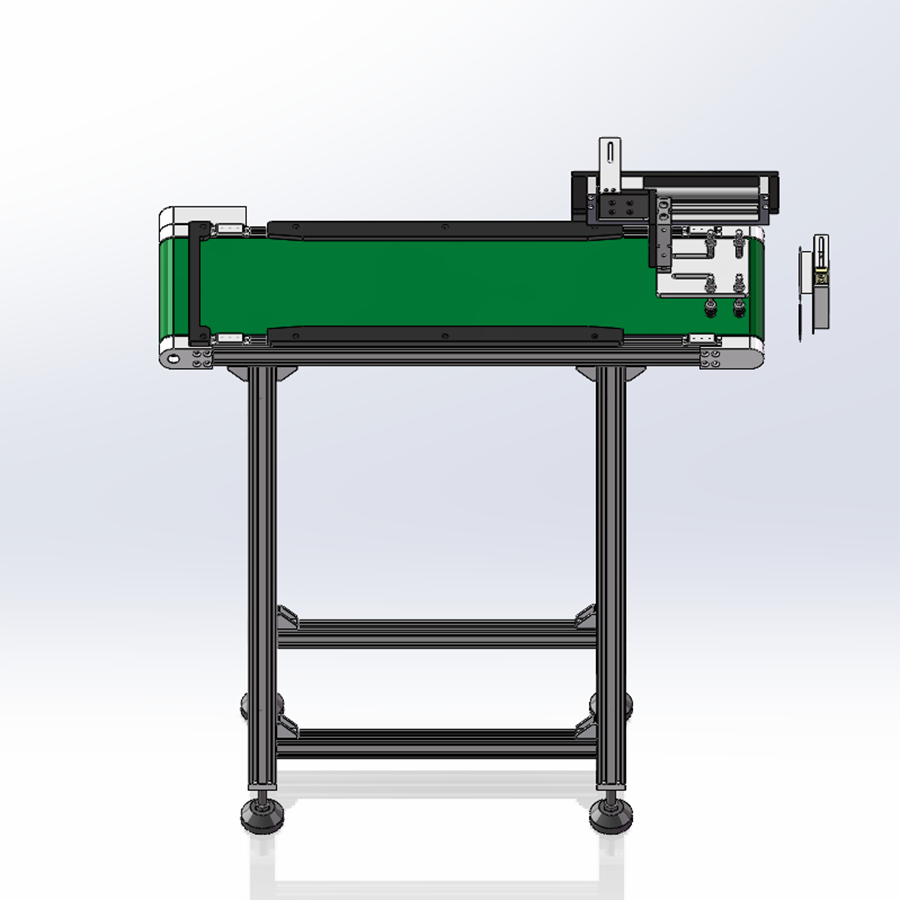

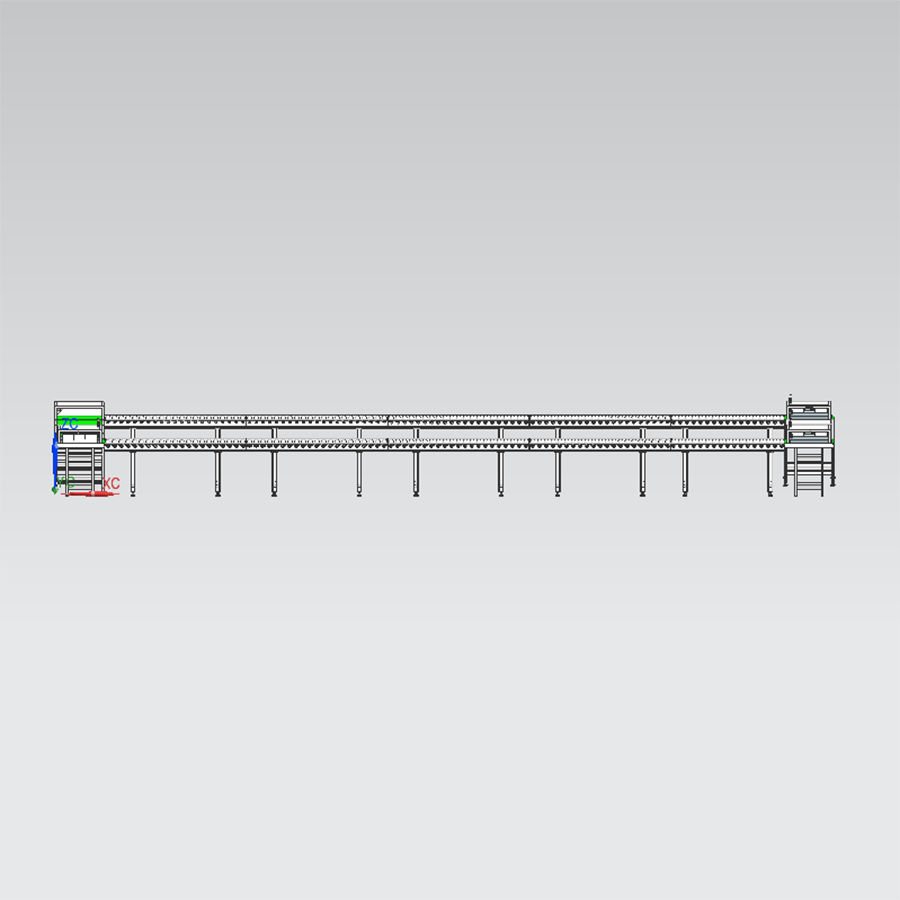

System architecture

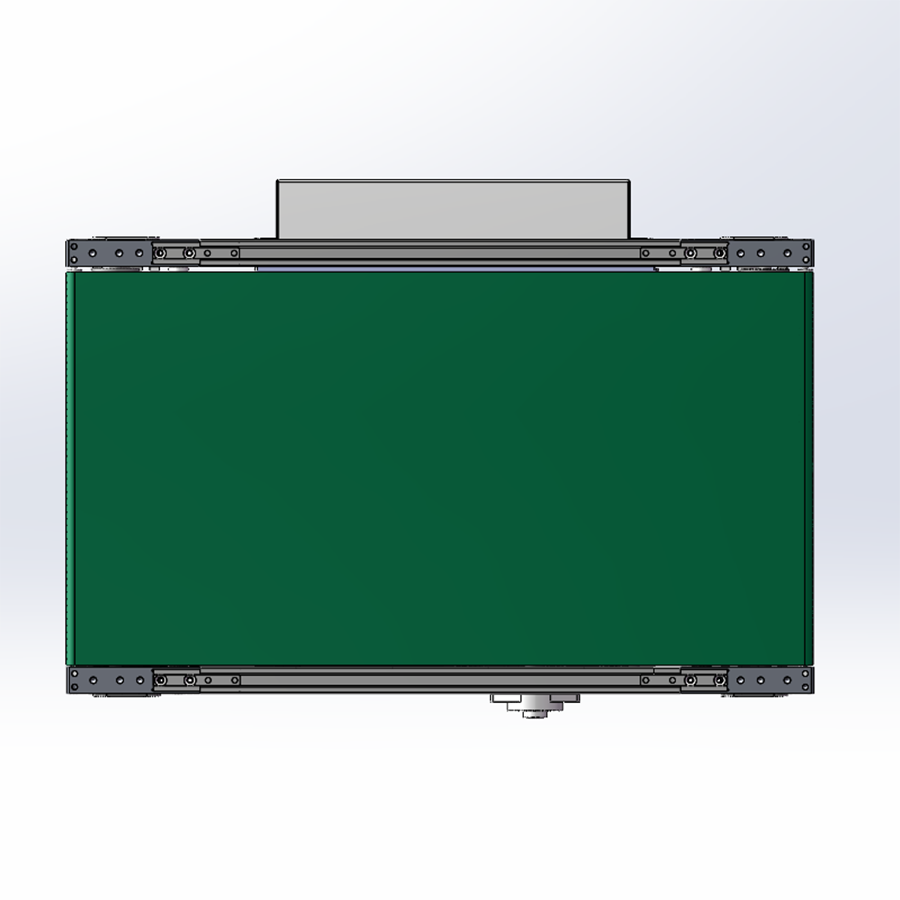

1. Anti-static design

PVC/PU and carbon fiber composite belts (surface resistance 10^6-10^8Ω)

Can be equipped with ion blower + grounding device (static voltage ≤50V)

2. Intelligent control system

Optional PLC control to link with upstream and downstream equipment.

Optional servo motor to improve positioning accuracy, and cooperate with the robot arm for repeated handling actions.

Can be used with a reader terminal for code scanning control.

Can be used with sensors for induction start and stop.

Customized expansion can be used to connect with other equipment.

3. Core functions

Inter-line linkage: Line linkage through IO/RS232 (optional)

Equipment collaboration: Precise grasping of upstream and downstream equipment and robotic arms (optional)

Abnormal interception: Automatic diversion of defective products (optional)

Implementation effect

Indicators Before and after transformation, the static defect rate dropped from 1.8% to 0.05%, the production capacity increased by 10%, and the labor cost of equipment docking was reduced by 5%

Promotion value

The solution has been promoted to 3C production lines, verifying its universality in miniaturized electronic assembly scenarios. The next step is to integrate the visual inspection module to build a fully closed-loop intelligent conveying system.